Processed by CNC milling turning machine, our standard carbon tubes can contain the position, shape, and size of the holes required by customers. The shape of the carbon fiber tube can be round, square, rectangle, hex and more.

CNC carbon tube processing often requires the help of fixtures. If the required holes are complex, custom fixtures are required

Our CNC machines are not limited to carbon fiber materials, we also can process other metals including aluminum, steel, stainless steel

1. Precision & clean product

We use computer-controlled machining to process. Aluminum parts' tolerance can reach +/-0.01mm. For carbon fiber products, we will deburr before shipping to ensure customers receive clean CNC carbon fiber machining parts.

2. Strong sense of confidentiality

We never share our customer's products with others and never share our customer's whole products on our website. We can sign NDA with our customers if needed.

3. Fast delivery

We have enough machines to process CNC machining parts. Customers don't need to spend too much time waiting.

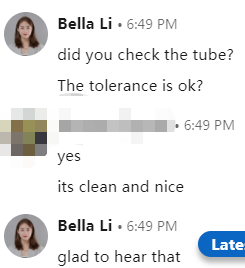

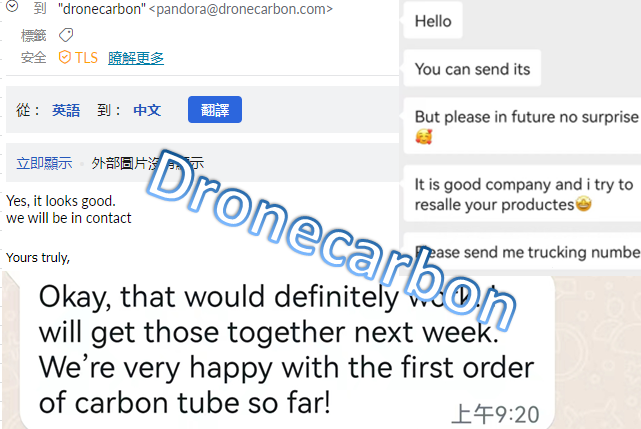

1. Customers reflected our carbon fiber square tubes' inner shape is clean and nice.

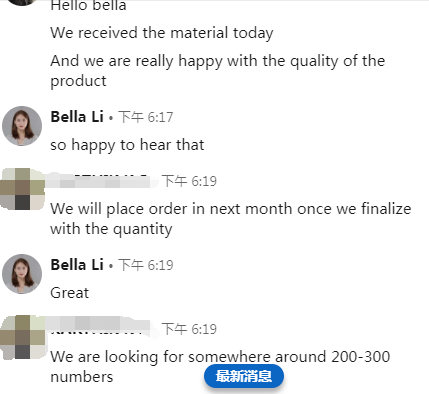

2. After customers test our sample, our customers confirm hundreds of tubes

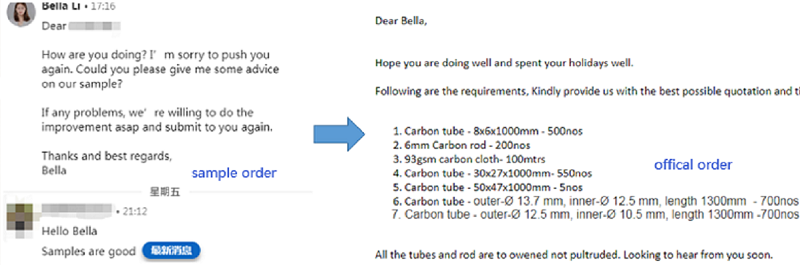

3. Cooperation case

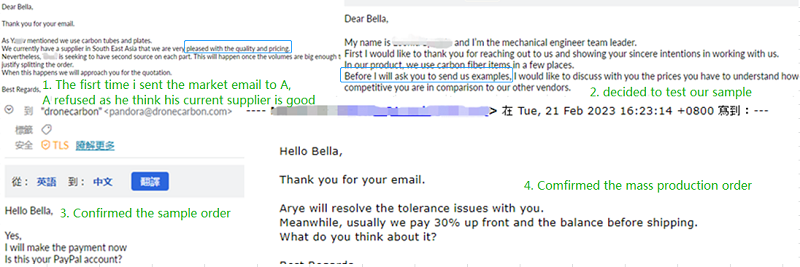

A customer refused to cooperate when i first time send the market email.

After testing our sample, he confirmed the mass production order with us.

4. Other feedbacks

It doesn't cost anything to send an inquiry. Why don't you send an instant inquiry to get the wholesale price?

pandora@dronecarbon.com