We have a dozen of cnc carbon fiber cutting machines to cut our customer's carbon fiber frames. Our customers don't need to be worried about slow lead time. All of our workers have full experience and most of them are work in this field for more than 10 years.

We can support special processes including adding the chamfer on the edge, adding the countersunk hole to match the flat head screws, adding the countersunk face, and so on.

After finishing carbon fiber cutting parts, we will also carry out a series of work to ensure that the final customer receives clean and no burr 3k carbon fiber CNC machined parts.

For the simple carbon fiber cutting parts, we can do one-step by CNC machines. But if your CNC parts need to add chamfer, countersunk hole or countersunk face, we need to do it second processing.

1. Add the chamfer

We can add the chamfer on the sides.

2. Add the countersunk hole

We can add the countersunk hole to match the flat head screw. Customers only need to let us know what size do you need to match with

3. Add the countersunk face

We can add the countersunk face according to the drawing.

![1666192392852420.png 2]I7D}RZJ7_C1V0V1P1YWMD.png](http://hk03-1251009151.file.myqcloud.com/dronecarbon.com/ueditor/php/upload/image/20221019/1666192392852420.png)

1. Double-check the drawing whether have duplicate lines

2. Layout the drawing

3. Control the CNC machine

4. Engineer QC the finished parts whether miss holes or cut the wrong size. pick out scratched parts

5. clean the burring piece by piece

6. Use plastic film to wrap the qualified CNC parts and put it in a carton bag.

1. Contact our sales team and send your drawing file to us.

If the drawing does not include special technology, (such as chamfer, countersunk) you only need to send 2D drawing for us. or you need to send Step file to us for check the detail.

2. Please let us know the surface, thickness, and quantity you need.

1. Rich experienced engineers serve with you.

90% of our engineers have more than 10 years of experience in operating CNC machines. It can well solve technical problems for you.

2. Customers can get precise CNC carbon fiber parts. The tolerance is only about +/-0.01mm

3. Fast delivery time.

Customers can get their CNC carbon frame in about 7 working days.

4. Customers' designs will not spread to the market.

We promised Dronecarbon never to share customers drawing with others.

5. Win more order

We guarantee our product quality and let our customers win more and more orders.

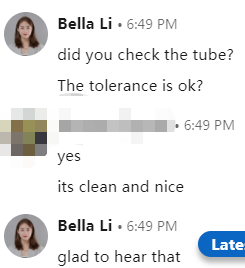

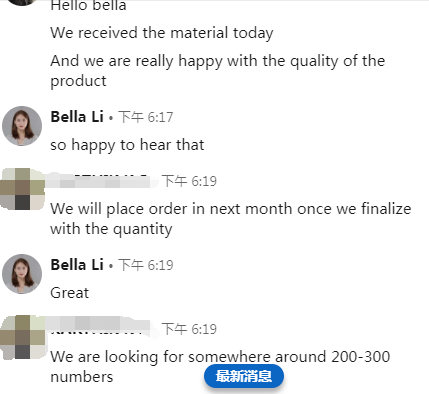

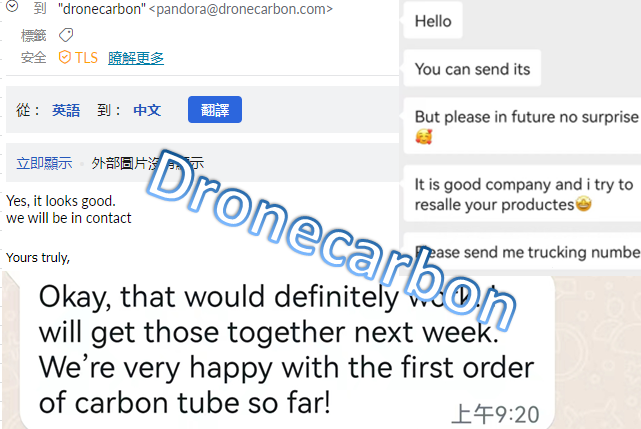

1. Customers reflected our carbon fiber square tubes' inner shape is clean and nice.

2. After customers test our sample, our customers confirm hundreds of tubes

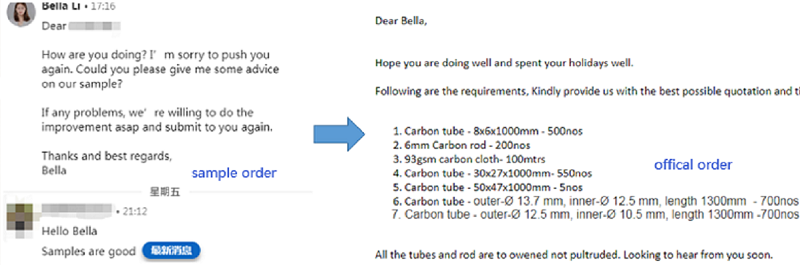

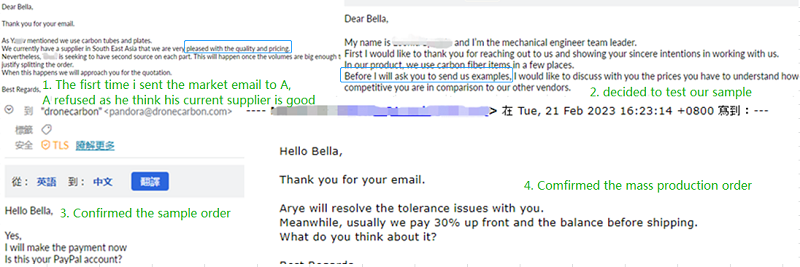

3. Cooperation case

A customer refused to cooperate when i first time send the market email.

After testing our sample, he confirmed the mass production order with us.

4. Other feedback

Q: Can you help me cut my own frame?

A: Yes, besides producing carbon fiber plates, we also can supply CNC cutting service

Q: What is your tolerance?

A: Our carbon fiber cutting tolerance can reach +/-0.1mm

Q: How is the maximum size and thickness you can cut?

A: biggest size we can cut is 2mx2m in size and 20mm in the thickness

Q: What is your MOQ?

A: We don't have MOQ. We are confident in our product quality. we welcome trial order before mass production.

Q: What is the production cycle?

A: It usually needs about 3-5 working days, also according to the order volume. We also can meet customers' requirements by adjusting our workshop schedule.

Q: Shipping way

A: We normally use DHL/FEDEX/UPS/TNT as it is fast. It usually takes 3-5 days to arrive.

It doesn't cost anything to send an inquiry. Why don't you send an instant inquiry to get the wholesale price?

pandora@dronecarbon.com